Capacity : 21-155 t/h

Motor Power : 800-3550 kw

Cylinder length : 3000~6000 mm

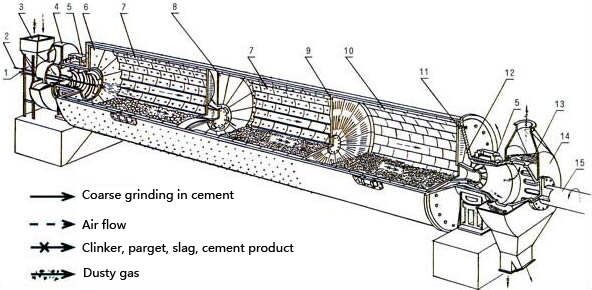

CHAENG energy-efficient ball mill equipment is new equipment to transform the basis of the traditional ball mill after, It changed the original mill structure, it is possible to reduce energy consumption by 30%, capacity increased by 15-20%, it is widely used in cement silicate products, new building materials, refractory materials, fertilizer, metal ore and glass ceramics etc. production industry.

The energy saving ball mill is a horizontal cylindrical rotating device, which has two cabins.

Ball mill is energy saving grate ball mill and the outside runs along the gear. The materials enter the first cabin of the mill spirally and evenly through the feeding apparatus and hollow shaft. In the first cabin, there is stepped liner or corrugated liner, and steel balls with different specifications. The centrifugal force generating from the rotation of the cylinder brings steel balls to a certain height, and then the balls fall, thumping and grinding the materials.

没有评论:

发表评论